The refining plants by OPI GROUP are designed and manufactured according to the customer’s needs and in compliance with anti-pollution regulations.

Acquaregia Gold refining system consists of one or more reactors made of PP, PVDF plastic material or TITANIUM, within which there is a rotating barrel built in the same durable materials; that allows a better dissolution of the alloy also with an hight percentage of silver inside.

Therefore, they are not static installations and allow high performance and a greater effectiveness and efficiency in the dissolution process.

Having a hot processing cycle requires lesser time than a cold processing cycle; combining it with a mobile system allows performing several dissolutions during the day.

The refining plants by OPI GROUP allow working 24 hours a day. The gold refining plant is equipped with: a frame made of AISI304/316 stainless steel, suction points, stair and walking surface with anti-slip resin flooring and Buchner filters. The system also includes an electric panel to control the machine actions and the process during the operation.

Smoke neutralization is implemented with fumes reduction scrubber sized according to customer requirements.

The dimensioning and design of the system, in terms of both quantities to be processed and positioning, will be decided together with the customer.

Acquaregia Gold Refinery MOD. K

- 100%

The reactor consists of an external container in PVDF or TITANIUM and an internal rotating cylinder and is complete with HEATING.

The internal cylinder is immersed in the dissolution liquid, the material to be processed never settles on the bottom of the reactor and by doing so there is no risk of being covered by silver chloride during processing (if the material is covered by silver chloride, dissolution material does not occur), this is because there are hundreds of holes on the rolling stock that allow the silver chloride to escape, keeping the material always in suspension while dissolution continues.

It allows grain (popcorn) to be processed with a high amount of silver and the heated reactor increases the reaction speed.

PVDF is a high-performance partially fluorinated thermoplastic polymer, characterized by good characteristics of chemical resistance to strong acids and oxidants, high solubility in polar solvents, resistance to ultraviolet rays and thermal applicability range: −40 °C / 140 °C.

TITANIUM is a metallic element well known for its resistance to corrosion, almost equal to that of platinum, and for its high strength/weight ratio. It is light, hard, with low density.

The dimensions are to be considered INDICATIVE and without stairs and/or walkways.

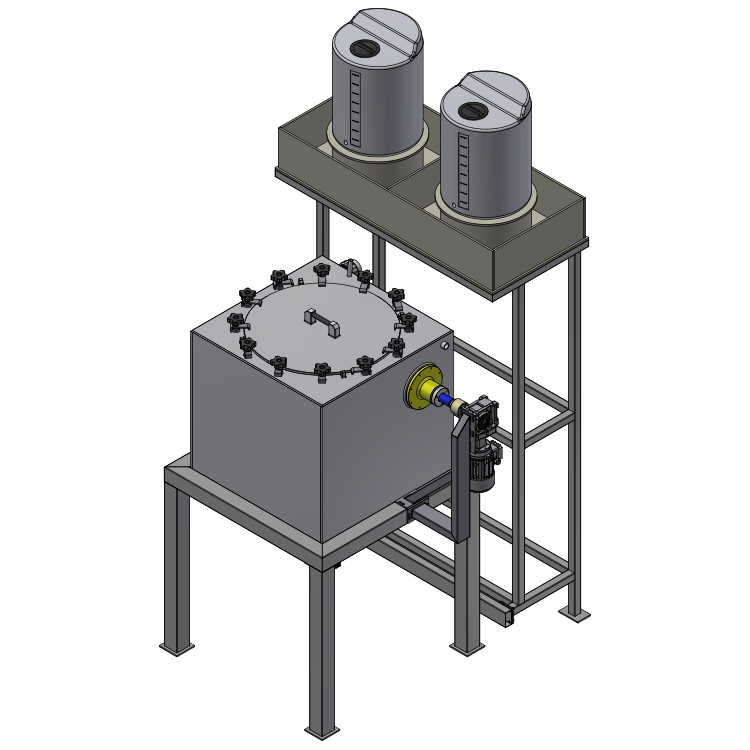

Acquaregia Gold Refinery MOD. RB

- 100%

This refinement system allows you to refine both grains (popcorn) and powders, it is easy to maintain, the TITANIUM model is heatable.

The dimensions are to be considered INDICATIVE and without stairs and/or walkways.

The dimensions are to be considered INDICATIVE and without stairs and/or walkways.

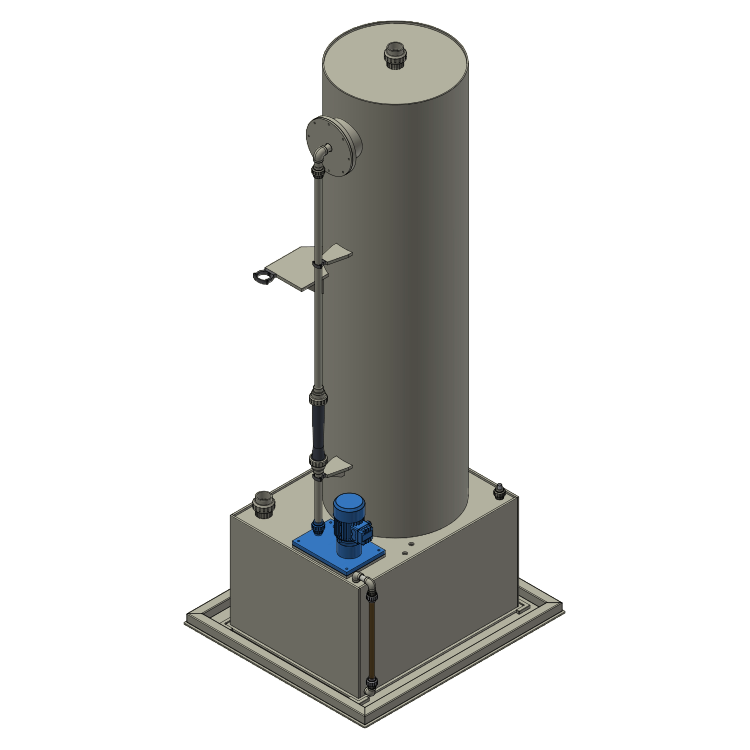

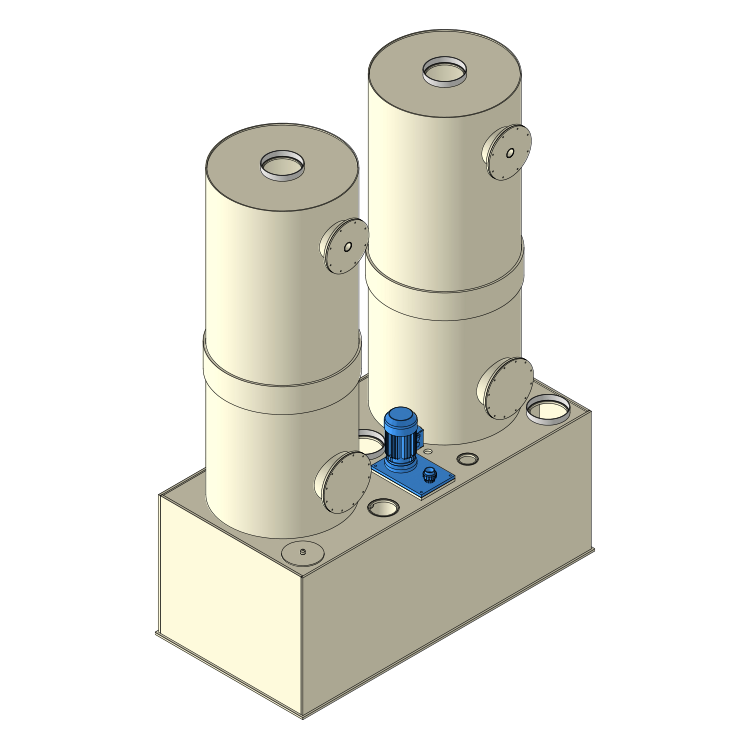

Basic Scrubber

- 100%

The dimensions are to be considered INDICATIVE and without stairs and/or walkways.

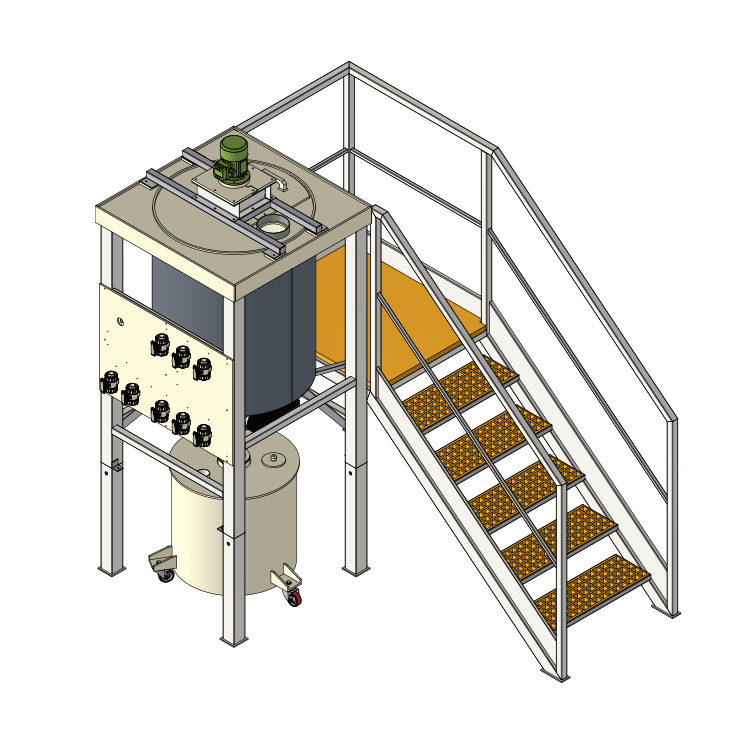

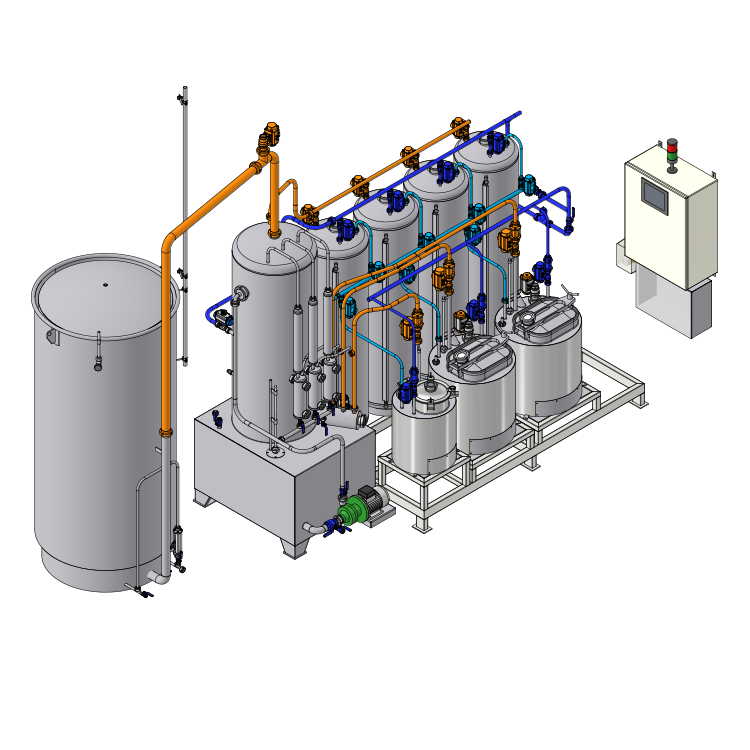

Inquartation System

- 100%

INQUARTATION SYSTEM by OPI Group serve to increase the quality of the alloy which will then be treated in the aquaregia refining system through dissolution with nitric acid. The systems are built with steel/titanium reactors and have the possibility of having a ZERO EMISSIONS system thanks to our installed gasometer.

All systems are modular, the customer could choose between different reactor sizes in the same machine.

The dimensions are to be considered INDICATIVE and without stairs and/or walkways.

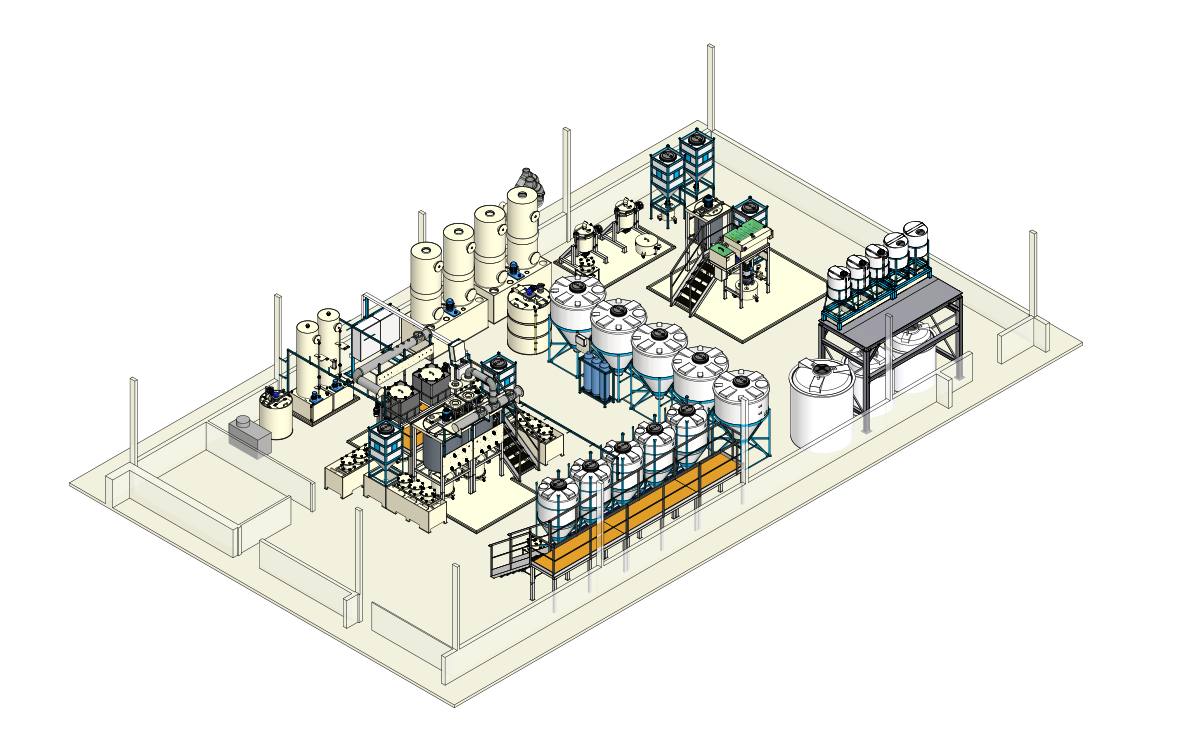

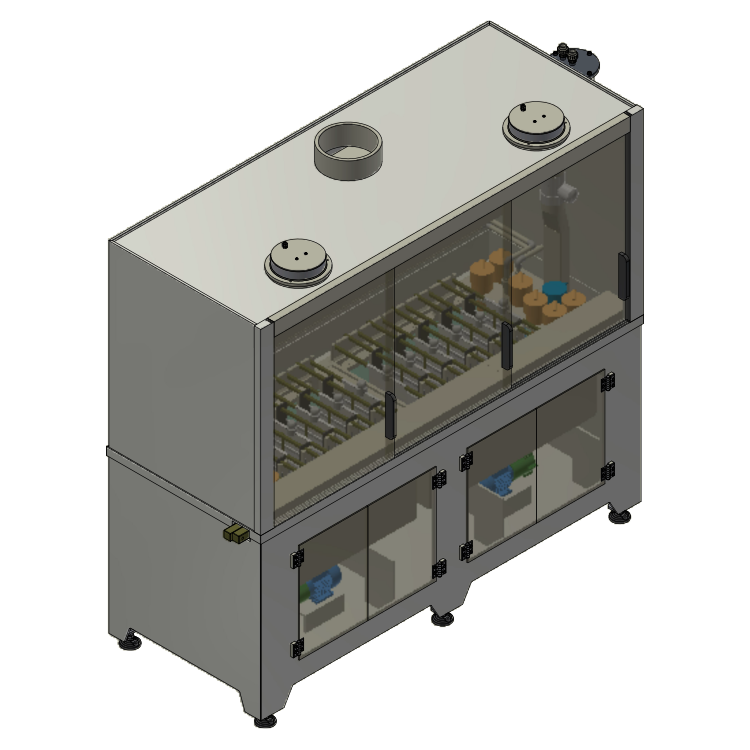

Gold Electrolysis

- 100%

The precious metals treatment and recovery system by OPI GROUP also includes the Gold Electrolysis process that allows obtaining a fineness of 999.9/1000 Au. Like all our systems, even these ones are sized according to the customer’s needs. The produced smoke is conveyed and neutralized in special smoke reduction towers, appropriately sized. The dimensioning and design of the system, in term of both quantities to be processed and positioning, will be decided together with the customer.

The dimensions are to be considered INDICATIVE and without stairs and/or walkways.

Contacts

La nostra competenza, la nostra consolidata esperienza e le risorse umane specializzate che compongono il nostro team ci permettono di garantire prodotti di alta qualità e di operare con la massima flessibilità.

Via Europa 45H, 36033 Isola Vicentina (Vi)

+39 0444 557454 SID. M5UXCR1

PEC: info@pec.opigroup.it

Cod.Fisc./Part.Iva/Registro Imprese: 04271770242

Cap. Sociale € 10000 – Num. REA 392312